Are you interested in designing you your own piece, don’t worry we got your back. Our qualified team of experts are willing to help you out with any question you have

Nylon 12 Powder

Why Opt for Nylon 12 Powder?

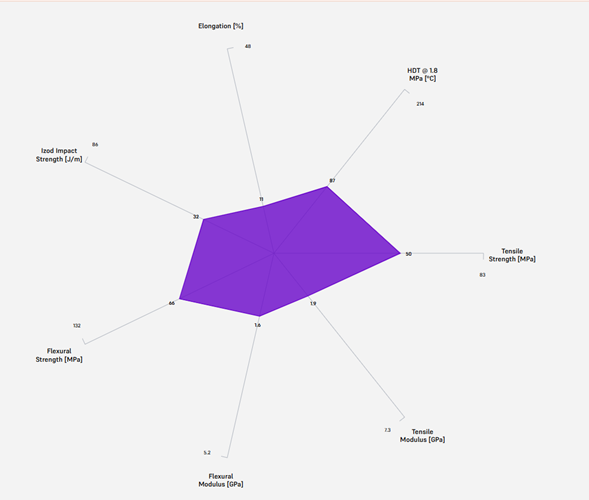

Material Properties NYLON 12

Mechanical properties

| MATERIAL PROPERTIES DATA | METRIC | IMPERIAL | METHOD |

| Ultimate Tensile Strength | 50 MPa | 7252 psi | ASTM D638 Type 1 |

| Tensile Modulus | 1850 MPa | 268 ksi | ASTM D638 Type 1 |

| Elongation at Break (X/Y) | 11% | 11% | ASTM D638 Type 1 |

| Elongation at Break (Z) | 6% | 6% | ASTM D638 Type 1 |

Flexural Properties

| MATERIAL PROPERTIES DATA | METRIC | IMPERIAL | METHOD |

| Flexural Strength | 66 MPa | 9572 psi | ASTM D 790-15 |

| Flexural Modulus | 1600 MPa | 232 ksi | ASTM D 790-15 |

Impact Properties

| MATERIAL PROPERTIES DATA | METRIC | IMPERIAL | METHOD |

| Notched Izod | 32 J/m | 0.60 ft-lb/in | ASTM D256-10 |

Thermal Properties

| Heat Deflection Temp. @ 1.8 MPa | 87 °C | 189 °F | ASTM D648 |

| Heat Deflection Temp. @ 0.45 MPa | 171 °C | 340 °F | ASTM D648 |

| Vicat Softening Temperature | 175 °C | 347 °F | ASTM D1525 |

Other Properties

| Moisture Content (powder) | 0.25% | 0.25% | ISO 15512 Method D |

| Water Absorption (printed part) | 0.66% | 0.66% | ASTM D570 |

Samples printed with Nylon 12 Powder have been evaluated

in accordance with ISO 10993-1:2018, and has passed the

requirements for the following biocompatibility risks:

Flammability Properties

| ISO Standard | Description 3,4 |

| ISO 10993-5:2009 | Not cytotoxic |

| ISO 10993-10:2010/(R)2014 | Not an irritant |

| ISO 10993-10:2010/(R)2014 | Not a sensitizer |

| Testing Standard |

| UL 94 Section 7 |

| Rating |

| HB * |

Thickness of the sample tested = 3.00mm

1

Material properties may

vary with part geometry,

print orientation and

temperature

2

Parts were printed using Fuse

1 with Nylon 12 Powder. Parts

were conditioned at 50%

relative humidity and 23 °C

for 7 days before testing.

3

Material properties may vary based

on part design and manufacturing

practices. It is the manufacturer’s

responsibility to validate the

suitability of the printed parts for

the intended use

4

Nylon 12 was tested at NAMSA

World Headquarters, OH, USA.

SOLVENT COMPATIBILITY

Percent weight gain over 24 hours for a printed 1 x 1 x 1 cm cube immersed in respective solvent:

| Solvent | 24 hr weight gain, % | Solvent | 24 hr weight gain, % |

| Acetic Acid 5% | 0.1 | Mineral oil (Heavy) | 0.7 |

| Acetone | 0.1 | Mineral oil (Light) | 0.5 |

| Bleach ~5% NaOCl | 0.2 | Salt Water (3.5% NaCl) | 0.2 |

| Butyl Acetate | 0.2 | Skydrol 5 | 0.6 |

| Diesel Fuel | 0.4 | Sodium Hydroxide solution (0.025% PH 10) | 0.2 |

| Diethyl glycol Monomethyl Ether | 0.5 | Strong Acid (HCl conc) | 0.8 |

| Hydraulic Oil | 0.6 | Tripropylene glycol monomethyl ether | 0.3 |

| Hydrogen peroxide (3%) | 0.2 | Water | 0.1 |

| Isooctane (aka gasoline) | <0.1 | Xylene | 0.1 |

| Isopropyl Alcohol | 0.2 |